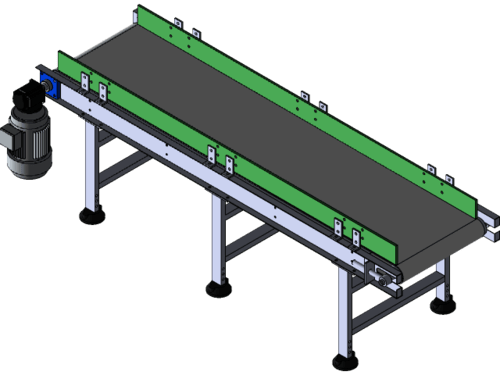

Belt Conveyor

A Belt conveyor is a material handling system that uses an effective and seamless technique to transfer supplies, materials, and components while saving time, energy, and money. The belt conveyor design includes two motorized pulleys with the conveyor material looped over them.

To initiate the belt conveyor's motion, the pulleys move at the same speed and in the same direction. All of the different types are used to convey materials and commodities along a continuous path. Though motorized conveyor belts are the most common type of conveying system, there are also systems that move goods using rollers without using a motor.

The carrying medium of a belt conveyor system, is one of the various types of conveyor systems available today, is a belt conveyor. To work effectively and perform the activities required by the belts, each belt conveyor system requires distinct modules.

Depending on the weight, the speed required, and the flow of items on the conveyor system, the various jobs might vary. A belt conveyor system is made up of two or more pulleys (also known as drums) that are connected by an infinite loop of carrying medium – the conveyor belt – those spins around them, pulling the things it transports. One or more of the pulleys that will be driven will move the belt and the material on the belt forward and along the system.

Types of belt conveyor

Roller Bed belt conveyor

The surface of a roller bed conveyor belt is a set of rollers that match the weight and speed required by the product. The number of rollers to be utilized is determined by the length of the roller bed conveyor belt.

For situations where materials are loaded by gravity, a roller bed conveyor belt is used. Because they are intended to decrease friction, they are an excellent choice for situations where items must be carried over long distances.

Flat belt conveyor

A Flat belt conveyor belt moves goods and supplies through a system of pulleys. Its belt is composed of natural or synthetic materials, making it adaptable to a wide range of situations and purposes. A flat belt conveyor belt may feature a central drive and nose bars in some cases.

Modular Belt Conveyor

A Modular belt conveyor is made up of interlocking hard plastic parts with readily removable and replaceable segments. Modular belt conveyors are easy to clean because of their design, and the material is resistant to sharp and abrasive substances. Modular belt conveyors are available in a variety of designs and employ a single belt to transport goods around curves, straight lines, up inclines, and downfalls.

Cleated belt conveyor

When the belt drops or inclines, Cleated belt conveyors contain sections, pockets, or dividers that keep granular items secure. The cleats are evenly spaced and available in a variety of forms and shapes, depending on the product to be transported and the belt's design.

Incline belt conveyor

The products on an Incline belt conveyor are held in place by a rough, uneven surface that prevents them from sliding or falling back. The belt's underside is silky, allowing it to slide softly across the bed. Conveyors with modular belts and timing belts can be utilized for this. Cleats may be incorporated for greater slippage prevention, depending on the material to be transported.

Filter belt conveyor

Unlike traditional belt conveyors, Filter belt conveyors enable items to travel through so that excess liquid may be drained from components or toxins and pollutants can be filtered out. To allow liquids and fluids to escape, filter belt conveyors are designed with lateral grooves and holes in the middle of the belt.

To prevent fluids from seeping into the belt fabric, drainage holes are put in a fabric-free zone down the middle of the belt or sealed. Filter belt conveyors, like sidewall conveyor belts, can feature sidewalls to prevent liquids and fluids from pouring over the belt's sides. For dewatering applications, they are composed of heated polyester, polypropylene, polyolefin, or stainless steel mesh.

How Conveyor Belts Work

As important as belt conveyors are to the efficiency of numerous industrial processes, their functioning is simple to outline. In essence, a belt conveyor is a broad, wide belt that looks like a giant rubber band and is attached to rollers in the shape of a loop that is connected to motorized rotors.

The belt conveyor, which is built of several sorts of tough and durable materials, is the design's loop. The belt's design offers structure and traction for the transportation of products and materials.

Motor

The rotors that move the conveyor belt are turned by the motor on a belt conveyor. The friction between the belt and the rotor is sufficient for the belt to adhere to the rotor. One side of the belt travels in one direction, while the other side moves in the opposite direction, due to the rotating action of the rotors. The conveyor belt moves as a result of the various actions.

Pulleys

Pulleys are located at the driving motor or each end of the belt conveyors. The conveyor belt is driven by the driving pulley, which has external bearings operated by a motor and reducer. Pulleys can be flat or crowned, with or without lagging to prevent belt slippage.

Return or tail pulleys, which have internal bearings and are situated at the end of the conveyor bed, and return the belt conveyor to the driving pulley. The purpose of tail pulleys is to keep the conveyor belt tensioned.

Rollers

The materials on the conveyor belt are supported by rollers as they move along the belt, and the belt is supported by rollers as it returns. A spring-retained axle is located in the Centre of a roller's shaft and is used to install and remove it. The amount of power required by the motor to move the conveyor belt is reduced by the position and positioning of the rollers.

Belt Conveyor

Conveyor belts come in an infinite variety of forms, sizes, shapes, angles, and materials. The design and kind of conveyor belt influence how it operates in a conveying system, and it is built to transport materials and goods from one area to another.

Belt Conveyor Applications

Any industry that involves the transfer of products or supplies from one location in the plant to another uses belt conveyors. It may not be essential to have a conveying system in small manufacturing enterprises since parts and components may be transferred utilizing a hand cart.

For efficiency, time savings, and production, larger, more complicated facilities require an automated system. Conveyor belts come in a wide range of sizes and applications, from little conveyors for moving jewellery and precious stones to massive conveyors for removing boulders, coal, and stones. A belt conveying system is most likely to be employed when speedy and cost-effective material moving is required.

Bulk Material

Bulk belt conveyors are used to transport both fine and granular materials as well as big lumps of material. Belt conveyors transport and load cement, sand, and gravel. To get to the raw materials in the mining business, coal, minerals, rocks, and stones must be extracted from mine shafts and open pit mines. To remove minerals and trash, belt conveyors of various lengths are introduced into the activities.

Unloading and loading of ships

When it comes to loading and unloading ships, mobility is critical. A belt conveying system unloads trucks and transports cargo into the ship's hold during the loading operation. The procedure is reversed during unloading, with cargo being transferred off the ship and delivered to trucks. Because of the particular nature of transportation and the many types of ships, loading and unloading belt conveyors may telescopically adjust to the ship's height.

Automated Assembly Line

Conveyors in assembly processes are specifically constructed to meet the demands of the activity. Belt conveying systems are continuously evolving to suit the various technological advancements and operational needs as more and more assembly operations use robotics and automated procedures. Chain, slider, hinged, plastic belt, and pallet are examples of belt conveyors used in automated assembly lines. The growing demand for quick and efficient material transportation has forced the development of novel belt conveyor topologies.

Our principal

Kiron Food Processing Technologies offers a complete belt conveyor system solution. Together, we look for cutting-edge technology in both material handling and information systems, as well as tried-and-true operating tactics.

For full, one-of-a-kind solutions, our specialists combine the strengths of scalable material handling systems, cutting-edge software, and bespoke automation engineering. Our objective is to use these tools to assist firms across a wide range of industrial areas in becoming industry leaders.