Frozen French Fries

Frozen French Fries are one of the most popular potato products globally, and they are usually made by cutting potato strips from fresh potatoes and deep-fat frying them. Frozen French fries are often heavy in calories and contain certain helpful elements such as minerals and vitamins due to their oil frying.

French fries, like potato chips, are a high-fat, high-energy snack. 100 g of full-fried frozen french fries has 312 kcal, 3.43 g protein, 14.73 g fat, 41.44 g carbs, 3.8 g total dietary fibre, 0.3 g sugars, and 1.85 g ash on average.

Frozen french fries are classified as extra long if they have more than 80 per cent strips of 2′′ lengths and 20 per cent or more strips of 3′′ length or longer; long if they have more than 70 per cent strips of 2′′ lengths and 15 per cent or more strips of 3′′ lengths or longer; medium if they have 50 per cent or more strips of 2′′ lengths or longer; and short if they have less than 50 per cent strips of 2′′ lengths.

Frozen french fries produced at home from fresh potatoes are superior to those purchased from a fast-food establishment. The recipe is at the bottom of the post, but the illustrated stages for blanching and freezing potatoes are below. A big saucepan, two large basins, a knife, a chopping board, a vegetable peeler, a slotted spoon, sheet trays, parchment paper, kitchen towels, and quart-sized freezer zipper bags are all needed to prepare your fries for freezing.

The golden colour, crisp outside surface, and mushy mealy inside indicate the quality of French fries. The colour light or light golden yellow is desired, whereas brown or black is undesirable. frozen french fries are made with potatoes with a creamy white to golden yellow flesh colour and a big to oblong tuber.

How are Frozen french fries made

Potatoes that have been cleaned and peeled are used to make frozen french fries. They are then sliced into slices and blanched in boiling water to slightly soften them. They are then flash-frozen and packed after cooling and drying. They are then fried in oil, with the surplus oil drained.

Potatoes must be peeled and chopped into strips to produce french fries. To remove the starch from the surface, they're usually rinsed or soaked in cold water after being sliced into strips. After all, it's the removal of the starch that makes your fries crispy rather than a crumbly mess.

Manufacturing Process of Frozen French Fries

Process of production

Grading, Dry sorting, Destoning, Peeling, Washing, and Packaging are all part of the production process. A little more trimming Defective potatoes, superfluous debris, and metal are all removed during dry sorting. Components, plastics, wood, and other materials are no longer needed.

The presence of stones in the tuber might be harmful. damage the blades, causing major complications while cutting As a result, it's important Especially in automated mechanical processing factories, to remove stones before cutting.

Potatoes are peeled with a carborundum or brush peeler, depending on their periderm thickness. For recently harvested tubers or immature periderm, brush peelers are the best option. Peeling can cause up to a 20% loss in hair volume. Peeling too much of the fruit might lower the yield. At this point, sorting and trimming flaws in the fried strips is considerably easier.

For cutting Frozen French fries, most people use water pistols with fixed knives that slice them lengthwise. After cutting the potato sticks, rinse them with plain water to eliminate any loose starch that may have accumulated on the surface. Because loose starch degrades the quality of frying oil and leaves black blotches on the chips, it must be removed.

After cutting, the raw potato sticks are blanched till transparent all the way through and then chilled. Blanching also helps to minimize sugars and stable colour, maintain product texture, limit fat absorption by gelatinizing the top layer of starch, and shorten frying time, in addition to enzyme inactivation.

After blanching, the strips are partially dried by being exposed to hot air currents to reduce moisture content. It is advised that excess moisture existing on the surface of the cleaned sticks be removed before frying, either by air pressure or centrifugal force, to decrease the hydrolytic breakdown of the oil. Excess moisture can quickly degrade the quality of frying oil due to thermodynamic effects.

The partly dried strips are then placed in a deep fat fryer for a brief time, at 350°F. A temperature of roughly 180-190 °C for the oil, during which the moisture content is increased even more The strips have been decreased in size and are just half cooked.

The strips are then quickly frozen at -18 degrees Celsius. -20 °C is the lowest temperature that can be reached. They may be stored in their frozen condition (-18 °C) for several months. Additional deep frying at a temperature of around 180-190 °C is required for eating these fries.

Food Packaging Role in the Manufacturing Process

Food packaging is both necessary and ubiquitous. Packaging is essential because food safety and quality would be jeopardized without it, and it is widespread since practically all food is packed in some fashion. Food packaging serves a variety of purposes, including protecting food from infection and spoiling.

It makes it simpler to carry and store meals, offers uniform content measurement, and allows for the creation and standardization of brands, which makes advertising more meaningful and large-scale distribution and mass retailing conceivable. Food packaging with dispensing caps, sprays, resealable apertures, and other characteristics improves product use and convenience.

Material for frozen French fries Packaging in Manufacturing Process

For quick Frozen French Fried potatoes, the packing material requirements for fresh consumption and frozen storage are different. Quick-frozen French fried potatoes require an extra 2-3 minutes of frying at 180-190°C before eating. This method of frying makes French fried potatoes crispier and more golden brown, which the consumer prefers.

These fries cannot be kept in sealed polymer bags at this time. Only paper/paperboard-based pouches and boxes are suggested as primary packaging. (Sealing the fries is not suggested since it alters their crispy texture.)

For storing in the freezer Primary or primary and secondary packing is required for French-fried potatoes. The principal packaging for par-fried fries is usually polypropylene or PET plastic pouches.

Primary packaging can also be made of low-density polyethene (LDPE) and high-density polyethene (HDPE). The high-speed filling can also be done with polypropylene coextruded with nylon bags, which are often individually fast-frozen (IQF) before package filling.

How to cook Frozen French fries

Fries should be kept frozen until ready to use. If you allow the fries to defrost before cooking, they will become mushy and brown. Baking, Air frying, and Deep-Frying in oil are all options for cooking your fries.

frozen french fries Baked in the Oven

Preheat the oven to 450 degrees Fahrenheit before baking the frozen fries. Spray a sheet pan with cooking spray, lay out the frozen fries, spray again and bake until golden and crispy, 12 to 15 minutes depending on the size, in a preheated oven. About halfway through, turn around. Season to taste and serve immediately.

Air Fryer Frozen French Fries

Preheat the air fryer to 400 degrees Fahrenheit before cooking the frozen fries. Cooking oil, such as avocado or vegetable oil, should be tossed or sprayed on the frozen fries. Use an oil sprayer instead of a cooking spray because the cooking spray isn't advised for air fryers. Place the potatoes in the air fryer basket and air-fried for 15 to 20 minutes, or until crispy. Toss halfway through to ensure that the fries cook evenly. Season to taste and serve immediately.

Our Principals

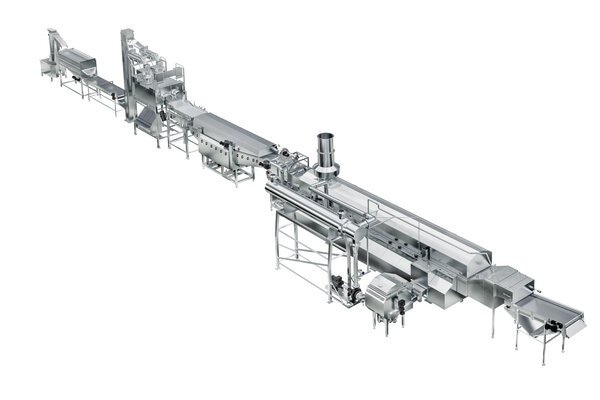

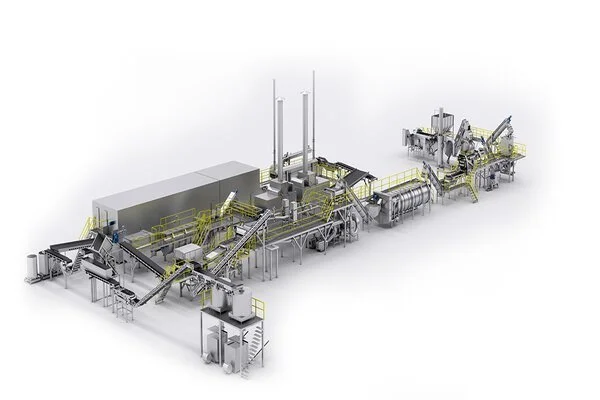

Tummers Food Processing Solutions and Rosenqvists with Kiron Food Processing technologies have been a leading manufacturer of machines, machine parts, and complete production lines for potato and vegetable processing.

The family company Tummers BV was founded in 1976 as an engineering company and the maintenance partner for the flourishing potato industry in the province of New Zealand.

Rosenqvists Food Technologies AB started in 2009 when a group of experts with long experience and background in the development and design of processing lines for the potato processing and snack food industries joined Rosenqvists.

Our focus is on processing lines for French fries and the snack food industry. Complete lines for potato chips and frying systems for pellets, prefabricated chips, peanuts, batch-fried chips, tortillas, wet pasta, etc.