Pickle Processing Line

The Pickle processing line is designed for the inactivation, colour fixation, packing, and sterilization of various types of pickled food. The enzyme activity in pickled vegetables is checked using a scaling machine, which maintains the distinctive fresh colour of fruits and vegetables, sends out the green odour of vegetables and retains the aroma, improves the suppleness of cells, and facilitates water evaporation.

Pickles are cucumbers that have been preserved in vinegar, salt, and other flavouring solutions. Before vinegar preservation, they are usually fermented with naturally existing bacteria. Pickles are still a popular cuisine, with over 5 million lb. consumed every day, even though the pickling technique has been around since ancient times.

Steam heating is the primary source of heat, and it consumes a lot of energy. The heating of heat transfer oil has several drawbacks. It will poison the whole pool of products if it spills. The equipment used in production differs depending on the time and temperature requirements of the product.

Except for basic pieces like the motor and bearing, the Pickle processing line is manufactured entirely of stainless steel SUS304, which satisfies all export food hygiene regulations. It has a bubble-producing mechanism that makes the material roll and removes agricultural residues from the product's surface. It can also be used with the appropriate amount of chemicals for disinfection and colour fixing.

To fulfil the cleaning goal, floating items can overflow from the overflow tank, and sediment can be released through the drain outlet. The equipment has the characteristics of high cleaning, energy saving, water saving, stable and dependable equipment, and can preserve the original colour under the combined operation of bubble, surf, lift, and spray.

Pickle processing line Raw materials

In the Pickle processing line, there are six primary categories of components. Cucumber is the primary bulk food. Acids, flavourings, colourants, preservatives, and stabilizers are among the extra substances in the liquid, or liquor, in which the pickle is marketed. Because many of the ingredients are only available at particular periods of the year, precautions must be taken to ensure that the supplies are fresh.

The cucumber is, without question, the most significant element in the Pickle processing line. Cucumbers with straight, thin skin, a predictable number of warts, and the correct size are produced using special seeds. These properties are critical in a pickle processing line that is consistent. Pickles may be produced using a variety of ingredients, including onions, peppers, olives, pears, peaches, and even fish and meat. To signify the sort of processing necessary to manufacture them, these are commonly referred to as pickled foods.

The main component in the Pickle processing line is acetic acid (vinegar). It makes up the majority of the pickle liquor after water and adds greatly to the flavour of the pickle by imparting a sour flavour. It also acts as a preservative and is harmless. Vinegar is made from sugars or starches that occur naturally through a two-step fermentation process.

Starch is transformed into sugar, which is subsequently fermented by yeast to produce alcohol. An acetobacter gets exposed to alcohol, which transforms it. Vinegar may be found in a variety of places, each with its distinct flavour.

As a result, depending on its source, vinegar can have a major impact on the final pickle product's flavour. Other components are added to the liquor, which influences the final taste of the pickles. Sugar is added to offer sweetness to balance out the vinegar's acidic flavour. It also aids in the plumping and firming of pickles. Artificial sweeteners such as aspartame and saccharine can be used to achieve the same result without adding calories. Salt is used as a taste enhancer as well as a preservative. Pure granulated salt is commonly used since it contains no anti-caking additives that might obscure the liquor.

To guarantee that the pickles fulfil the requirements specified in the Pickle processing line, several extra components may be added. Pickles, in general, do not require colourants because their natural colour is sufficient. Manufacturers frequently add colour to provide a consistent product and to counteract the impacts of treatments like bleaching.

Turmeric caramel and chlorophyll are two popular colourants. Caramel gives the colour a somewhat brown to yellow hue, while chlorophyll gives it a green hue. Sulfur dioxide is added to pickles to prevent colour changes. Lime and alum, for example, can be used as firming agents.

Pickle processing line Process

Cucumbers are gathered by field workers and placed in huge bins before being transported to a receiving point. Refrigerated trucks are used to carry cucumbers over great distances. This helps to keep the vegetable's fresh look and flavour. The cucumbers are poured out onto a conveyor at the reception station, where they are cleaned to remove any extra stems, blooms, dirt, or other foreign substances.

Because tiny levels of germs on unwashed cucumbers might spoil the final pickle product, this step is critical. They are then transported to an inspection station, where any rotting vegetables are removed and the remaining veggies are sorted by size. They're then transported to a chiller and kept until they're ready to eat.

In a Pickle processing line, the cucumber can be converted into a pickle in one of three ways: fermentation, pasteurization, or chilling. Fermentation is the first and most traditional procedure. Cucumbers are transported to big, airtight fibre-glass or stainless-steel containers in this approach. These canisters can store up to 40,000 pounds of cucumbers. The brine solution, which is made up of water and 10% salt, is pumped into the tanks.

The manufacturer has the option to take action. The fermentation bacteria break down the sugars in the vegetable and create carbon dioxide over a five-week storage period. The tanks are frequently degassed to avoid negative effects from the carbon dioxide. Pickles prepared in this manner have a distinct flavour.

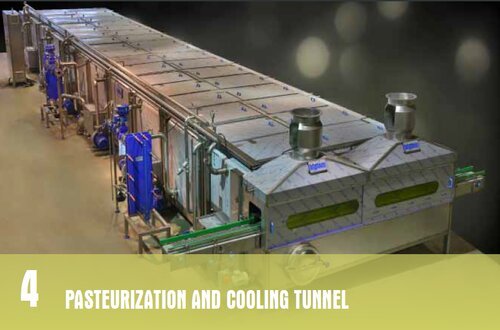

The other two preservation techniques do not need a fermentation stage. Direct pasteurization is one way. Cucumbers are bottled and then subjected to extremely high temperatures for a specified period in this Pickle processing line procedure. This has the effect of destroying all of the naturally occurring germs. Cucumbers that have been sterilized can subsequently be turned into pickles. Pickles produced in this manner have a short shelf life of only a few months.

Refrigeration and acidification are the third methods. To keep these pickles from spoiling, they need to be kept at a cool temperature and in a vinegar solution. They are faster to produce, but their shelf life is much shorter. The salt solution is emptied when the pickles have matured sufficiently. After that, the pickles are submerged in water to eliminate any salt that may have accumulated during the cure. The pickles are then transported down a conveyor to a slicing machine, where they are chopped to the appropriate size based on the sort of product requested.

They can be chopped, sliced into slices, or even cut into chips. Pickles are kept in as clean an environment as possible to avoid contamination by bacteria, which might result in an unsatisfactory product. Pickles are normally stored in glass jars after being sliced, however, cans, plastic bottles, and pouches have also been used. The packaging machines are made to supply the right amount of product.

Benefits of using pickle processing line

1. The Pickle processing line can clean, soak, colour protect, package, sterilize, and sterilize pickled vegetables and rhizome pickled goods, among other things.

2. In the transmission component of the Pickle processing line, a SUS304 stainless steel mesh belt is utilized, which has a steady operation, a long service life, and fulfils food hygiene standards.

3. Easy to use, easy to maintain, and easy to connect.

4. High level of automation, easy to operate and maintain.

5. The sink's main stainless steel is 304 stainless steel, which is 2mm thick.

Our Principal

Kiron Food Processing Technologies, in association with Bigtem, provides a full solution for your Pickle processing line requirements.

Bigtem is a world leader in this industry, producing processing lines for more than half of the raisins produced worldwide. With the manufacturing lines it has created in the last ten years, Bigtem has given traditional processing methods a whole new viewpoint. Raisin processing lines combine the greatest levels of sanitation with the lowest operational and capital expenses.

Our simple-to-use, low-maintenance lines provide shredding, rewashing, and packing services to countries such as Germany, the Netherlands, England, and Canada, where grapes are not grown but merely consumed.