Screw Feeder

In the fast-paced world of food processing and manufacturing, effectiveness is important. Screw feeder must be faster, smarter, and more reliable than ever ahead. numerous of these procedures calculate on an obscure idol the screw feeder.

It's neither spectacular nor noisy, but it plays an important role in ensuring the continuous, steady flow of supplies and when that is developed by a Dutch perfection specialist, similar to Klinkenberg B.V., and manufactured and maintained in India by Kiron Food Processing Technologies, you have the ideal mix of European imagination and Indian specialised skill.

But what makes this cooperation special? And why should enterprises in India and away pay particular attention to this screw feeder? Let's have a quick look.

What is a Screw Feeder, and Why Does It Matter

Before we go into the company behind the product, it's important to understand what a screw feeder performs.

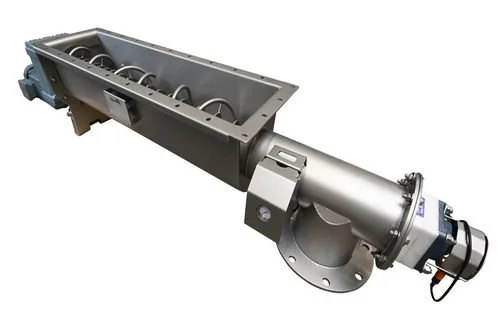

A screw feeder is a mechanical device used to manage the inflow of bulk materials. It moves grainy or powdered material by turning a spiral screw blade, also called as an auger, which is typically housed inside a tube. While it may appear easy, getting it right is an engineering art.

Screw affluents are extensively used in diligence like

Their capacity to ensure nonstop material inflow makes them useful, especially when factors need to be combined, cured, or conveyed precisely. In diligence, similar to food, hygiene, perfection, and responsibility are not just desirable, but are needed.

A heritage of Precision Engineering

Klinkenberg B.V., headquartered in the Netherlands, is not your ordinary engineering business. With over 75 years of experience, they have established themselves as the global leader in screw conveyor and screw feeder technology. Klinkenberg is well-known for its durable, pristine sword products, as well as its commitment to quality, innovation, and precision.

What distinguishes Klinkenberg is its thorough mindfulness of consumer demands. Every screw feeder Kiron Food Processing Technologies develops is more than simply a machine; it's a result. Their designs are extremely configurable, designed to integrate into current manufacturing processes painlessly, and finagled to repel indeed the most delicate accoutrements, whether sticky, abrasive, or temperature-sensitive.

The Design Edge

Screw Feeder are designed with rigidity in mind. This translates to lower time-outs during conservation, further long-term inflexibility, and easier upgrades. Features may include.

Variable pitch screws for steady inflow.

Aseptic and durable sealed bearing assemblies

Custom cove outlets for flawless integration with colourful processing systems

Voluntary heating or cooling jackets

Easy-to-clean shells for food safety compliance.

When working with cocoa greasepaint in a chocolate factory or rice flour in a snack food plant, these things are important.

Further Than Manufacturing

While Klinkenberg leads in design, Kiron Food Processing Technologies is responsible for manufacturing, installation, and servicing in India. Kiron Food Processing Technologies, headquartered in India, has sluggishly risen to become a trusted name in the food processing industry, representing colourful top-league transnational companies throughout the key.

Their relationship with Klinkenberg exemplifies smart globalisation by combining European technological power with India's product dexterity and cost effectiveness.

Kiron Food Processing Technologies does more than just assemble and distribute these machines; we also customise them for Indian circumstances. We have a strong understanding of the Indian food business, including its climate, raw materials, and manufacturing issues. This sapience guarantees that every screw feeder is made not just to worldwide norms, but also to meet original conditions.

Kiron Food Processing Technologies also gives comprehensive after-sales service, installation support, and on-point customisation, distinguishing itself from numerous import-only rivals. Do you need a screw feeder for turmeric greasepaint in Tamil Nadu or flour in Punjab? Kiron Food Processing Technologies can modify the arrangement to your exact preferences.

Why This Collaboration Works

1. Engineering Meets Prosecution

This cooperation between Klinkenberg and Kiron Food Processing Technologies ensures access to state-of-the-art European technologies in India, cost-effectiveness without compromising quality, original support, and compliance with EU and Indian food safety norms.

2. Assiduity Concentrated Customisation

Unlike general conveyors, the Kiron Food Processing Technologies screw feeder is customised for each purpose. Affluents can be customised for low-capacity spice dosing or high-volume flour conveying based on factors such as speed, inflow rate, auger pitch, face finish, and robotisation integration (PLC control).

This rigidity is especially important in India's expanding food processing sector, where businesses are looking to automate while retaining traditional product attributes.

3. Hygiene and Safety First

Screw affluents used in food grade operations must be readily gutted, erosion resistant, and devoid of impurity enterprises. The Klinkenberg design satisfies HACCP, FDA, and EHEDG conditions. Kiron Food Processing Technologies assures that this standard of safety is maintained throughout the product and servicing processes in India.

Case Study - Real World Operations

Case 1 Snack Food Manufacturer – Maharashtra

A famed snack manufacturer in Maharashtra needed a Screw feeder that could handle fine besan (gram flour) at a regular pace for their automatic mixing line. Kiron Food Processing Technologies delivered a modified Klinkenberg design with a variable-speed drive, polished internals, and a dust extraction system. The end effect was better batched delicacy and lower home made running.

Case 2 Spice Processor – Kerala

Handling spice maquillages like turmeric and chile may be delicate since they are fine, sticky, and reactive. A spice exporter from Kerala came to KFPT for help. A Kiron Food Processing Technologies Screw feeder with a Teflon- carpeted screw and specialanti stick liner was added, vastly adding inflow and dwindling conservation time.

Case 3 Pharma Ingredient Mixing – Gujarat

Pharmaceutical grade greasepaint mixing necessitates delicacy and minimum impurity. A pharmaceutical establishment in Gujarat demanded a screw feeder that met GMP conditions. Kiron Food Processing Technologies banded on a result that includes a completely sealed casing, a CIP(clean-in-place) technology, and pristine sword construction.

Sustainability and effectiveness

Sustainability is no longer a term in modern society; it's an absolute need. Both Klinkenberg and Kiron Food Processing Technologies agree on this point.

Variable frequency drives maximise energy effectiveness.

Precision feeding minimises waste and increases batch uniformity.

Durable accoutrements and easy conservation lead to a longer lifetime and lower frequent reserves.

Kiron's original servicing also results in smaller shipping and a lower carbon impact than a wholly imported outfit.

The Future of Material Handling in India

India's artificial and food sectors are reaching a tipping point. As automation becomes more available, the demand for smart, effective, and aseptic material handling systems rises. The screw feeder, once a silent idler on the product bottom, is now an important part in this shift.

Indian businesses may profit from Klinkenberg's world class design experience and Kiron's manufacturing prowess and request sapience, furnishing them with a result that's completely integrated rather than just imported.

Final studies

When you invest in a screw feeder designed by Klinkenberg and manufactured by Kiron Food Processing Technologies, you are not just copying an outfit. You are investing in decades of engineering invention, indigenous moxie, and a cooperation model designed to help your company for many years to come.

Whether you are a launch-up ramping up product or a transnational expanding in India, our partnership provides a dependable, evidence based result for your material running conditions.

NOTE

In an age where robotisation and localisation are no longer voluntary but needed, this cooperation illustrates how the styles of both worlds, Dutch delicacy and Indian pragmatism, can join together to manufacture Screw Conveyors.