SORTING MACHINE

Our Principal Optimum Sorting develops the world's most exceptional Sorting Machine. Food Cultivators, Packers, and Processors throughout the planet utilize Optimum Sorting to sort an assortment of new items and prepare food to boost output and minimize waste.

Benefits of Sorting Machine

Maximized yield and recovery, while decreasing food waste.

Sustainable activities that optimize resources.

Increased efficiency and throughput with high-capacity Sorting.

Ensure premium quality, So your items accurately represent your brand.

Types of Sorting Machines

Optical Sorting Machine

An Optical Sorting Machine is fundamental in any processing operation. An optical Sorting machine sorts grain, food, and plastic, assisting you with meeting food handling necessities and accomplishing cleaner product quality. Our Sorting machine utilizes a scope of innovations, including cameras, lighting, and Machine learning software. It eliminates item abandons and unfamiliar materials by shading, shape, and surface. We likewise have a broad item range dependent on a financial plan, limit, and the item quality you need to accomplish.

Camera Sorting Machine

The Kiron Food Processing Technologies camera sorting machine is the best and most cost-effective sorting machine for the frozen food, vegetable, and organic product handling industry. The Optimum gives nonstop food inspection to guarantee sanitation and consumer loyalty consistently by eliminating undesirable unfamiliar material, staining, and deformed items, with maximum yield!

Innovative optical setup

Compact and clean design

Innovative graphical UI

Focus Sorting Machine

The FOCUS is an Optical Sorting Machine that is particularly appropriate for arranging items with different optical inadequacies. Staining, disfigurement, and unfamiliar items are distinguished and precisely eliminated from the item stream.

The FOCUS Sorting Machine might be utilized on a stream of Fresh, Dried, Frozen Potato products, Vegetables or Fruit products, and also Crustaceans and Shellfish.

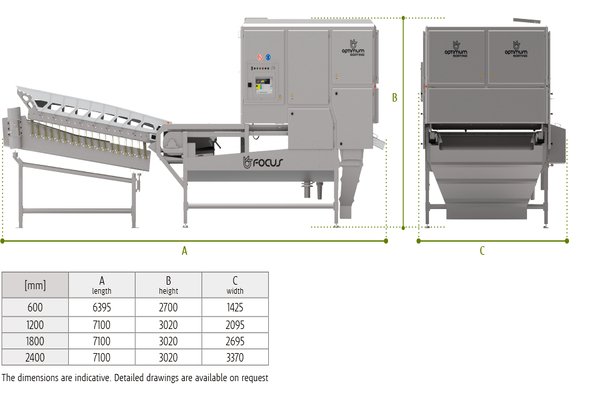

The FOCUS Sorting Machine is accessible in four models with a scan width of 600, 1200, 1800, or 2400mm.

Features & benefits of Focus Sorting Machine

The FOCUS Sorting Machine is an optical belt sorting machine specially created for sorting items with random imperfections. Stains, shape deviations, and unfortunate constituents are distinguished in the item stream and eliminated with high accuracy. The utilization of FOCUS not only prompts a greater of your final result but also lower and more predictable production costs.

The FOCUS Sorting Machine recognizes your item on the fast-rotating item perusing belt utilizing inventive identification methods. Your item is distinguished and precisely eliminated. You are immediately informed regarding the choices taken by the FOCUS dependent on the rules you have entered. The particular development of the FOCUS makes it conceivable to choose from, the perfect combination of camera, light, and other techniques for the best sorting results.

Broadest optical belt sorter

Phenomenal good-to-bad ratio

Unique camera arrangement for French fries, Carrot cubes, or other Root vegetables

3R laser class

Sorting based on Shape, Structure, and colour

24/7 (remote) service

Maintenance-friendly

Fast product switching

Extremely user-friendly operation

Nexus Sorting Machine

The NEXUS is a Sorting Machine exceptionally created for sorting items with various optical imperfections. Stains, shape deviations, and undesirable constituents are recognized in the item stream and eliminated with high accuracy.

The utilization of the NEXUS Sorting Machine is not just promoting a greater of your final result, but additionally lower and more unsurprising production costs.

The NEXUS Sorting Machine has a creative, controlled item feed, which can adjust to the size of your item. A feed belt guarantees that the items arrive in the review and launch region at a similar speed.

This controlled item supply and internal resorting stream increase the certainty with which good and bad products are detected and ejected. You see this reflected in your great item and the optimal good-to-bad ratio.

The secluded development of the NEXUS Sorting Machine makes it possible to choose from the ideal mix of camera, light, and different strategies for the best sorting results.

The NEXUS Sorting Machine is accessible in two models with a working width of 1000 or 1200 mm. This implies that the machine can undoubtedly be incorporated into a current item arranging line.

Optimum Sorting also impacts the total designing of your optical arranging line: the NEXUS including feed vibrator, product (re-)routing, and desired modules can be adapted to your requirements in the existing or new production line.

Compact freefall sorter

Durable LED lighting

Advanced camera

Smart algorithms

Internal resorting stream (DRS)

Excellent good-to-bad ratio

Sorting based on colour, shape, and structure

24/7 (remote) Service

Maintenance-friendly

Fast product switching

Extremely user-friendly operation

TRIPLUS Sorting Machine

The TRIPLUS Sorting Machine is an optical sorter particularly created to sort items with different optical deficiencies. Staining, distortion, and unfamiliar items are recognized and precisely eliminated from the product flow.

TRIPLUS Sorting Machine can be utilized for entire potatoes, vegetables, the organic products just as fish. Utilization of the TRIPLUS will prompt, quality improvement of your result, in addition to lower and more predictable production costs. The TRIPLUS is accessible in three models with a scan width of 840, 1200, or 1800mm.

The double ejection unit enables us to split the product flow into three flows, for example:

Accept item

Product to be reprocessed

Foreign bodies

Features & benefits

The utilization of the TRIPLUS Sorting Machine not only prompts a more excellent finished result but additionally lower and more unsurprising creation costs. The TRIPLUS has a creative, controlled item feed, which can adjust to the size of your item. A discretionary adjustment belt guarantees that the items arrive at the assessment and launch region at a similar speed. This controlled item supply builds the sureness with which great and awful items are recognized and launched. You can see this reflected in your food product and the optimal good-to-bad ratio.

The secluded development of the TRIPLUS makes it conceivable to choose the ideal mix of camera, laser, and different methods for the best-arranging results. Also, 3 unique sizes are accessible with the goal that the machine is impeccably adjusted to your production capacity.

VENTUS Sorting Machines

Ventus Sorting Machine has been exceptionally created for arranging nuts and dried fruits and is additionally great for frozen vegetables, berries, and other small items. Since the Ventus utilizes lasers with a higher yield, the difference between good and bad products is likewise much clearer, bringing about ideal deformity location and excellent goods too bad ratio.

One or two sides of laser modules in the mix with innovative software calculations guarantee solid location and productive dismissal of an assortment of deformities; like stains, distorted, unfamiliar materials, and primary contrasts. With its noteworthy laser filter speed of 3300 sweeps each second, the Ventus offers the most elevated goal of all sorters on the lookout. The Ventus Sorting Machine is accessible in different output widths, 600mm up to 1800 mm, and can deal with enormous limits.

With the Ventus sorting machine you will experience improved and steady item quality and reduced yield losses which result in a significant reduction in labor costs.

NOVUS Sorting Machines

Optimum launched their newest optical belt sorter called the Novus Sorting Machine. The base edge of the Novus has been overhauled to conform to the strictest hygiene standard principles and the latest machine rules. Besides, the gear is modular, so it tends to be effectively arranged, as per the requirements of the client, and it can likewise be extended with similar adaptability after establishment.

In recent years, the organization has efficiently developed and further developed its past Focus product offering, at last uniting every one of the advancements in another item. The outcome is another belt sorter, for certain novel components for significantly more precise arranging.

As indicated by a public statement, the Novus Sorting Machine is outfitted with metal identification innovation, making it the main machine available that joins three arranging advancements. The M-TEC module built into the frame detects and removes tiny Stainless Steel, Ferrous, and Non-ferrous metal particles that the cameras and lasers might not detect. The module is made up of several smaller coils, which means that its detection sensitivity is greater than that of traditional metal detectors.

The Novus Sorting Machine is also equipped with advanced high-resolution cameras (RGB, IRGB, InGaAs, or IR) known from the Focus, but the camera mounting has been improved and the focal points advanced. Moreover, the 5/6 setup for the arranging of diced potatoes and other tuberous vegetables is as yet accessible. Another expansion is the S-TEC module, which likewise assesses the lower part of the item, which is especially intriguing for dry items," organization agents clarify.

To increase its sorting accuracy, the Novus can be equipped with the most recent age laser scanner, which was created for the Ventus, and this can be utilized for a checking width of 1800 mm without forfeiting execution. "For instance, the Novus has a noteworthy laser filtering rate of up to 4000 outputs each second, bringing about an optical goal of 0.3 mm, the most elevated goal of any laser sorter available," says the organization.

The launch module was additionally redesigned. New launch valves have been presented that can switch quickly and have a more extended life. Ideal calls attention to the that their machine utilizes normalized valves, which are a lot less expensive as far as fixing and upkeep.

The Novus sorting machine will be accessible in different widths from 600 to 2400 mm. The Novus 1200 and Novus 1800 are now being carried out, while the 2400 and 600 will be accessible in the second and third stages.

Kiron Food Processing Technologies is leading the resource revolution and aiding our clients to maximize their profit and product capacity. Increasing safety and traceability helps everyone, upstream and downstream, and most importantly the people who are preparing dinner for their families at the end of the day.

Our proactive and predictive maintenance and sorting technology utilize data to increase operational effectiveness, decrease waste, and give you peace of mind knowing your products are safe enough for your own family. Your trusted partner in Kiron Food Processing Technologies is here to support you, every step of the way, operating for our customers in India. A sustainable future is only achievable when we work together to make the most out of what we have. Contact us to receive details on your specific application.